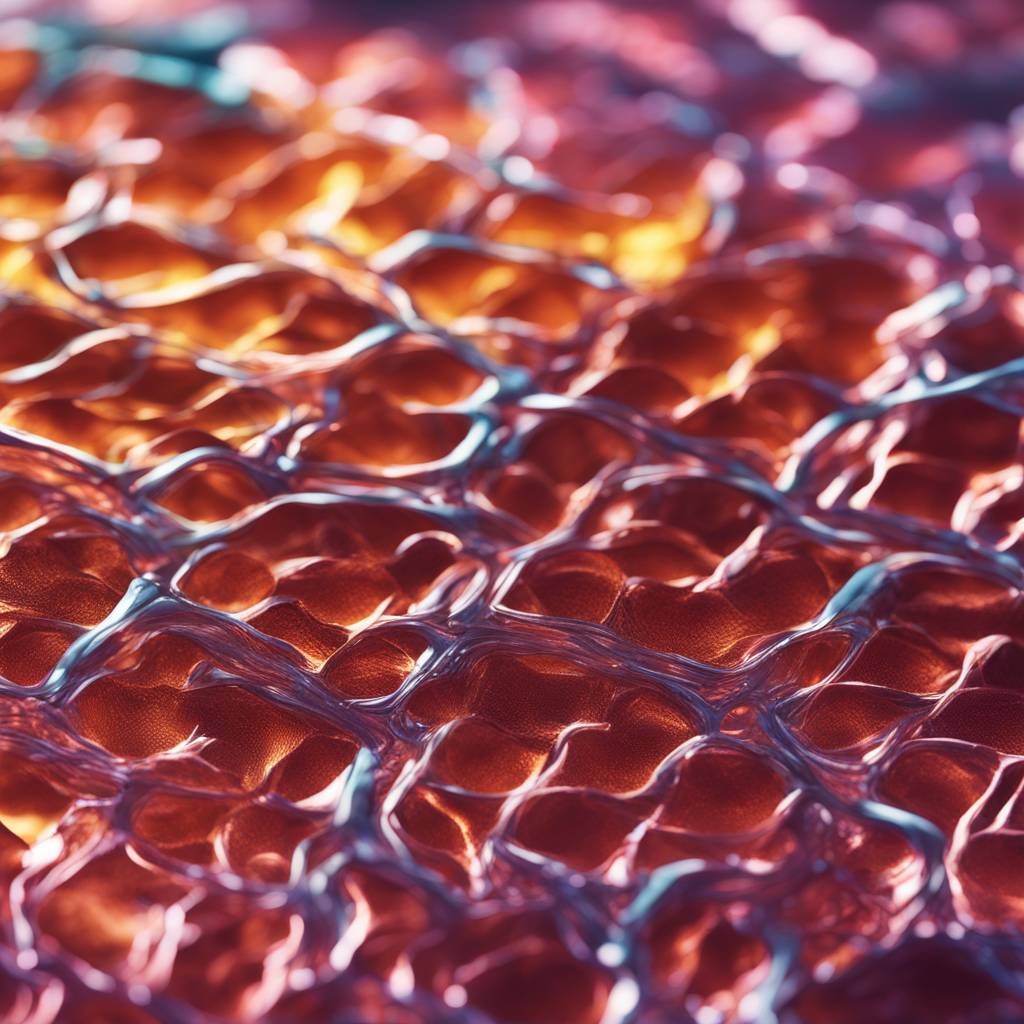

Toray Industries, a Japanese performance chemical manufacturer, has developed a new ion-conductive polymer membrane that boasts 10 times the ion conductivity of its previous iterations. This advancement in technology is achieved through hopping conduction, which allows lithium ions to move between interacting sites within the polymer membrane by jumping across sites. The non-porous membranes have been enhanced by improving the hopping site structure and designing a new polymer with more hopping sites, resulting in an ionic conductivity in the range of 10-⁴ S/cm for a hopping-conductive polymer film. This polymer film has also been proven effective as a protective film on lithium metal surfaces, increasing the longevity of batteries that use lithium metal lithium anodes.

Research conducted in collaboration with Professor Nobuyuki Imanishi of Mie University’s Graduate School of Engineering has demonstrated the successful completion of 100 charge-discharge cycles in a dual-component lithium-air battery utilizing Toray’s new polymer membrane as a separator. The company believes that this innovative offering could accelerate the adoption of solid-state batteries, air batteries, and other lithium metal batteries, thereby expanding the range of electric vehicles, industrial drones, urban air mobility systems, and various other modes of transportation.

The development of the ion-conductive polymer membrane with enhanced ion conductivity through hopping conduction represents a significant technological breakthrough that could revolutionize the energy storage industry. By allowing lithium ions to traverse more efficiently within the membrane, the new polymer offers improved performance and longevity for batteries, particularly those using lithium metal anodes. The ability to extend the service lives of batteries with lithium metal anodes opens up new possibilities for applications in electric vehicles, drones, and other transportation systems, enhancing their efficiency and sustainability.

Toray Industries’ collaboration with Professor Nobuyuki Imanishi of Mie University has provided valuable insights into the practical applications of the new ion-conductive polymer membrane. The successful completion of 100 charge-discharge cycles in a lithium-air battery employing this membrane as a separator demonstrates its reliability and durability in real-world scenarios. This milestone achievement paves the way for the commercialization and implementation of the technology in a wide range of energy storage devices, including solid-state batteries and air batteries, further contributing to the advancement of sustainable transportation solutions.

The potential impact of Toray Industries’ ion-conductive polymer membrane extends beyond the energy storage sector, with implications for various industries and applications. By enabling the deployment of solid-state batteries, air batteries, and other lithium metal batteries, the new membrane technology could facilitate the development of more efficient and reliable energy storage solutions for electric vehicles, drones, and urban air mobility systems. This innovative technology has the potential to revolutionize the way we power transportation and other sectors, leading to cleaner, more sustainable modes of operation and reducing our reliance on traditional fossil fuels.

With its breakthrough in ion conductivity and hopping conduction technology, Toray Industries is positioned as a key player in advancing the capabilities of energy storage systems. By improving the efficiency and longevity of batteries using lithium metal anodes, the company’s innovative polymer membranes have the potential to address key challenges in the electrification of transport and other industries. As the demand for sustainable energy solutions continues to grow, Toray’s ion-conductive polymer membranes could play a crucial role in accelerating the transition to a cleaner, greener future, offering enhanced performance, reliability, and durability for a wide range of applications.